The Power of Cold Steel: Tools in Skilled Hands

RR

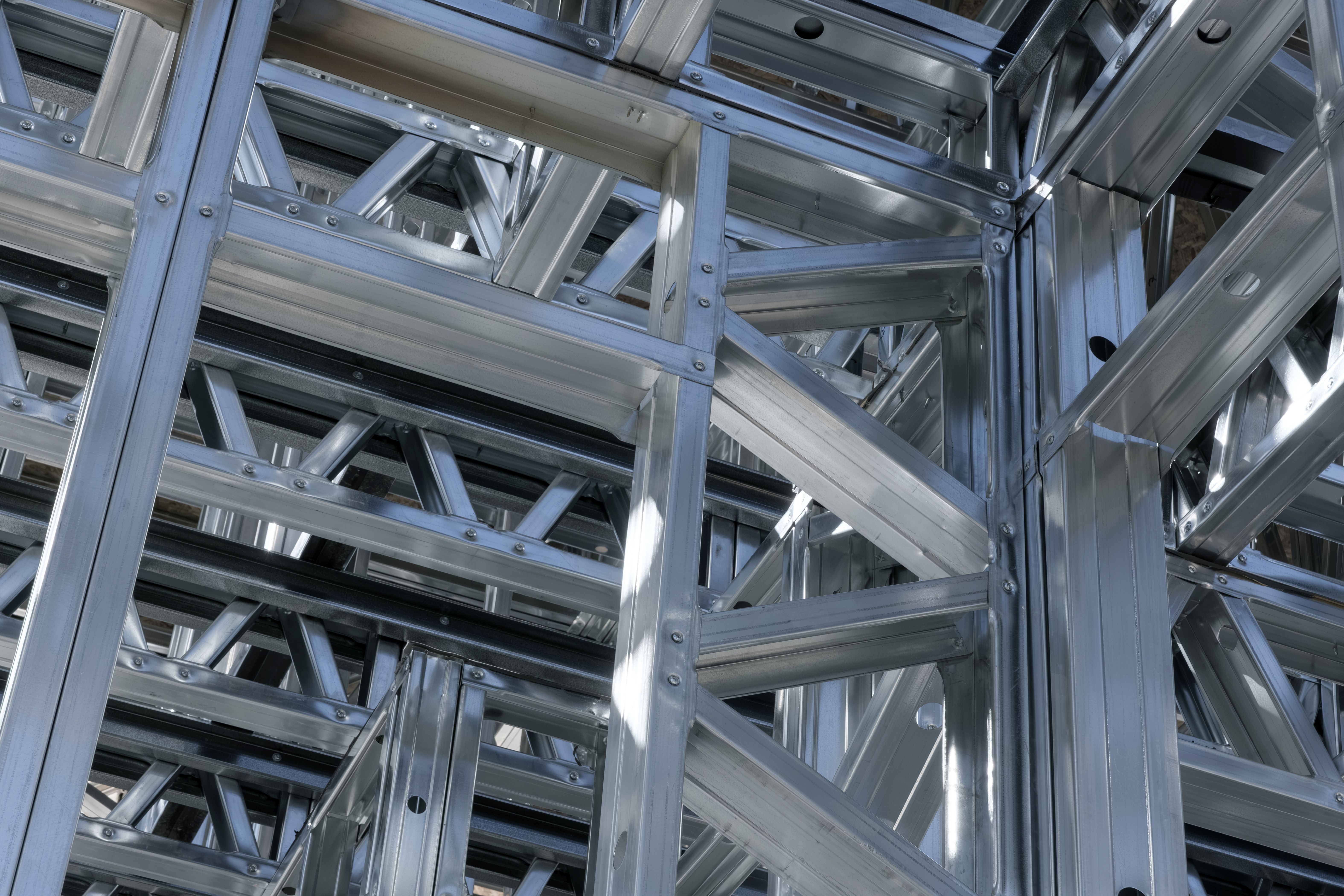

The Timeless Appeal of Cold Steel

In a world where technology seems to evolve faster than ever, there's something profoundly reassuring about the solid, dependable nature of cold steel. These tools have stood the test of time, serving as extensions of skilled hands across countless industries. Whether it's a blacksmith shaping metal or a chef wielding a knife, the **power of cold steel** is undeniable.

The journey of steel from raw material to finished tool is a fascinating one. It involves a series of processes that transform a simple alloy into an instrument of precision and strength. The result is a tool that not only performs but also inspires confidence in its user.

The Craftsmanship Behind Every Tool

Every tool crafted from cold steel carries with it a legacy of craftsmanship. Skilled artisans pour their expertise into each creation, ensuring that every piece meets high standards of quality and durability. This attention to detail is what sets these tools apart from their mass-produced counterparts.

Artisans employ a variety of techniques to forge these tools, each step meticulously executed to enhance performance. From tempering to sharpening, the process requires patience and precision. The end product is more than just a tool; it's a work of art that reflects the skill and dedication of its maker.

The Importance of Balance

A well-balanced tool is crucial for effective use. The weight and distribution of cold steel tools are carefully considered during design and production. This balance allows for greater control and reduces user fatigue, enabling skilled hands to work with greater efficiency and accuracy.

Applications Across Industries

Cold steel tools find applications in a wide range of industries, each with its own unique demands. From construction to culinary arts, these tools are indispensable. Their versatility and reliability make them the go-to choice for professionals who require consistent performance.

In the culinary world, for example, chefs rely on precision knives to create culinary masterpieces. These knives must maintain a sharp edge while being durable enough to withstand constant use. Similarly, in construction, workers depend on sturdy tools that can endure harsh conditions without compromising functionality.

The Role of Innovation

While the basic principles of cold steel tools remain unchanged, innovation continues to play a significant role in enhancing their capabilities. Advances in metallurgy and design have led to the development of new alloys and improved ergonomics. These innovations ensure that tools remain relevant in an ever-evolving landscape.

Maintaining Cold Steel Tools

To ensure longevity and optimal performance, maintaining cold steel tools is essential. Regular cleaning and proper storage can significantly extend the life of these tools. Sharpening blades and applying protective coatings are also important practices that help preserve their effectiveness.

Proper maintenance not only protects the tools but also ensures safety for the user. A well-maintained tool is less likely to fail, reducing the risk of accidents in the workplace or at home.

A Legacy of Excellence

The enduring legacy of cold steel tools is a testament to their excellence. They represent the pinnacle of human ingenuity and craftsmanship, embodying both tradition and innovation. As long as there are skilled hands to wield them, these tools will continue to play an essential role in countless industries around the world.

In conclusion, the power of cold steel lies not only in its physical properties but also in its ability to empower those who use it. Through skill and dedication, these tools become more than just instruments; they become partners in creation and innovation.