How to Choose the Right Annular Cutter for Steel Structures: A Comprehensive Guide

RR

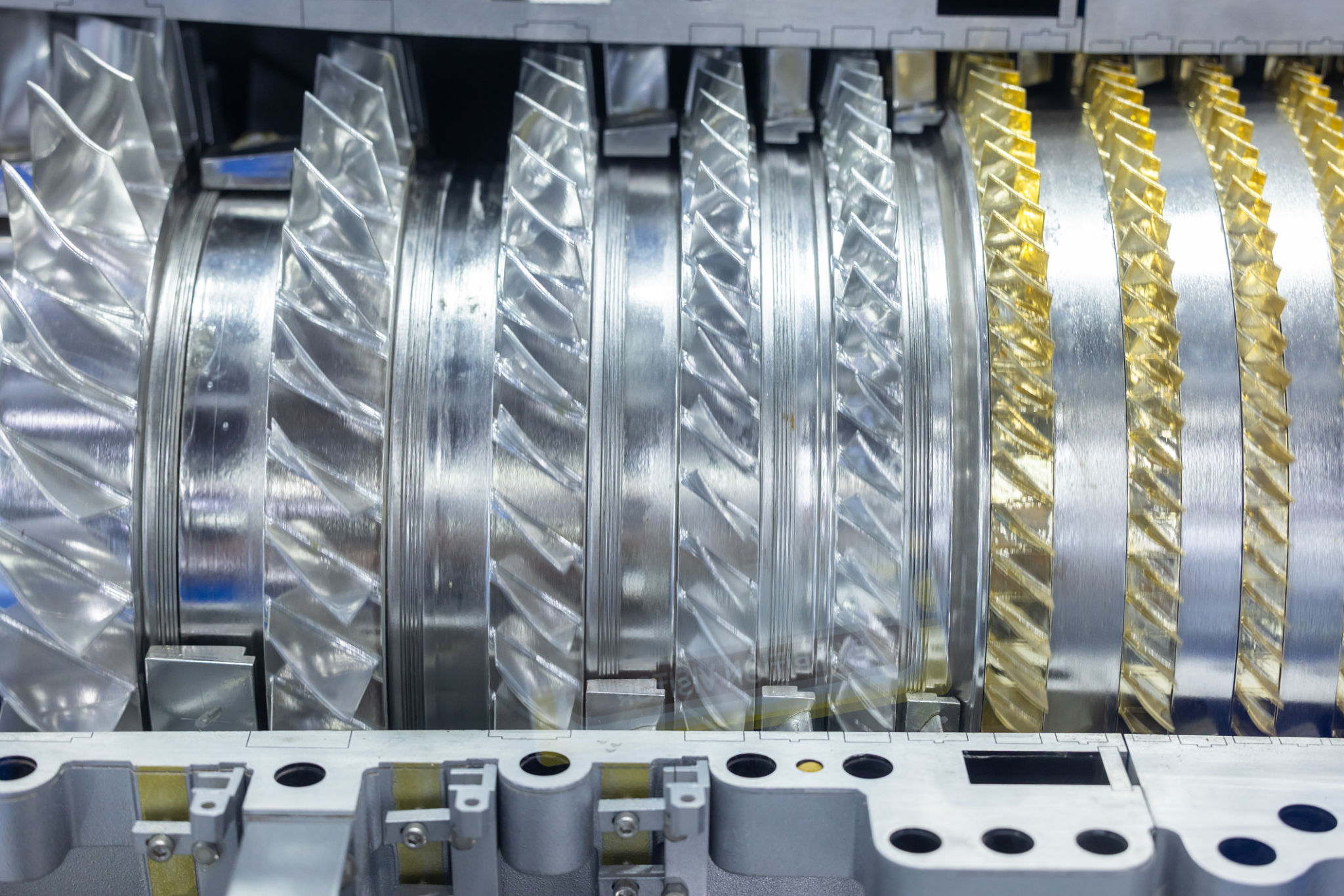

Understanding Annular Cutters

Annular cutters are essential tools for creating precise holes in steel structures. Unlike traditional twist drills, annular cutters remove only the material around the edge of the hole, creating a clean, burr-free finish. This feature makes them ideal for structural steel applications where precision and efficiency are paramount. Choosing the right annular cutter can significantly impact the quality of your work and the longevity of your tools.

When selecting an annular cutter, it's crucial to understand the different materials and coatings available. High-speed steel (HSS) cutters are known for their durability and cost-effectiveness, while cobalt cutters offer enhanced heat resistance, making them suitable for tougher materials. Carbide-tipped cutters provide the best performance in hard materials but come at a higher price point. Consider the specific needs of your project to determine which material will offer the best results.

Size and Compatibility

The size of the annular cutter is another critical factor to consider. Annular cutters come in various diameters and depths, so it's essential to choose one that matches your drilling requirements. The diameter should correspond to the size of the hole you need, while the cutting depth should accommodate the thickness of the material you're working with.

Compatibility with your drilling equipment is also vital. Ensure that your annular cutter is compatible with your magnetic drill or other power tools. Most cutters come with a standard shank size, but it's always best to double-check before making a purchase. Investing in an adapter might be necessary if your tool requires a different fitting.

Understanding Coatings and Features

Annular cutters often come with various coatings designed to enhance performance and longevity. Titanium nitride (TiN) coatings, for instance, can reduce friction and increase wear resistance, extending the life of your cutter. Other coatings like titanium aluminum nitride (TiAlN) provide additional heat resistance, which is beneficial when working with high-speed applications.

Consider additional features such as pilot pins, which help center the cutter and improve accuracy, or ejector pins, which assist in removing the slug from the hole. These features can enhance efficiency and reduce downtime during operations, making them valuable considerations when selecting an annular cutter.

Budget and Quality

Your budget will inevitably play a role in choosing the right annular cutter. While it might be tempting to opt for the most affordable option, investing in a high-quality cutter can save you money in the long run by reducing tool wear and improving productivity. Consider well-known brands that offer reliable performance and customer support.

Moreover, assess user reviews and industry recommendations to gauge the quality and reliability of different annular cutters. Real-world feedback can provide insights into a product's performance and help you make a more informed decision.

Final Considerations

Lastly, consider the specific requirements of your project when choosing an annular cutter. Factors such as speed, accuracy, and material hardness should guide your selection process. By taking into account all these elements—material type, size, compatibility, coatings, features, budget, and quality—you can make an informed choice that ensures optimal performance for your steel structure projects.