Exploring Lincoln Electric USA's Innovations in Welding Technology

RR

The Legacy of Lincoln Electric USA

Founded in 1895, Lincoln Electric USA has been a trailblazer in the field of welding technology. With over a century of experience, the company has continuously set benchmarks for innovation and quality. Their commitment to excellence has established them as a global leader, providing cutting-edge solutions to industries around the world.

Lincoln Electric's dedication to technological advancement has been unwavering, allowing them to remain at the forefront of welding technology. Their products are known for their reliability and efficiency, which is why they are trusted by professionals across various sectors.

Revolutionary Welding Technologies

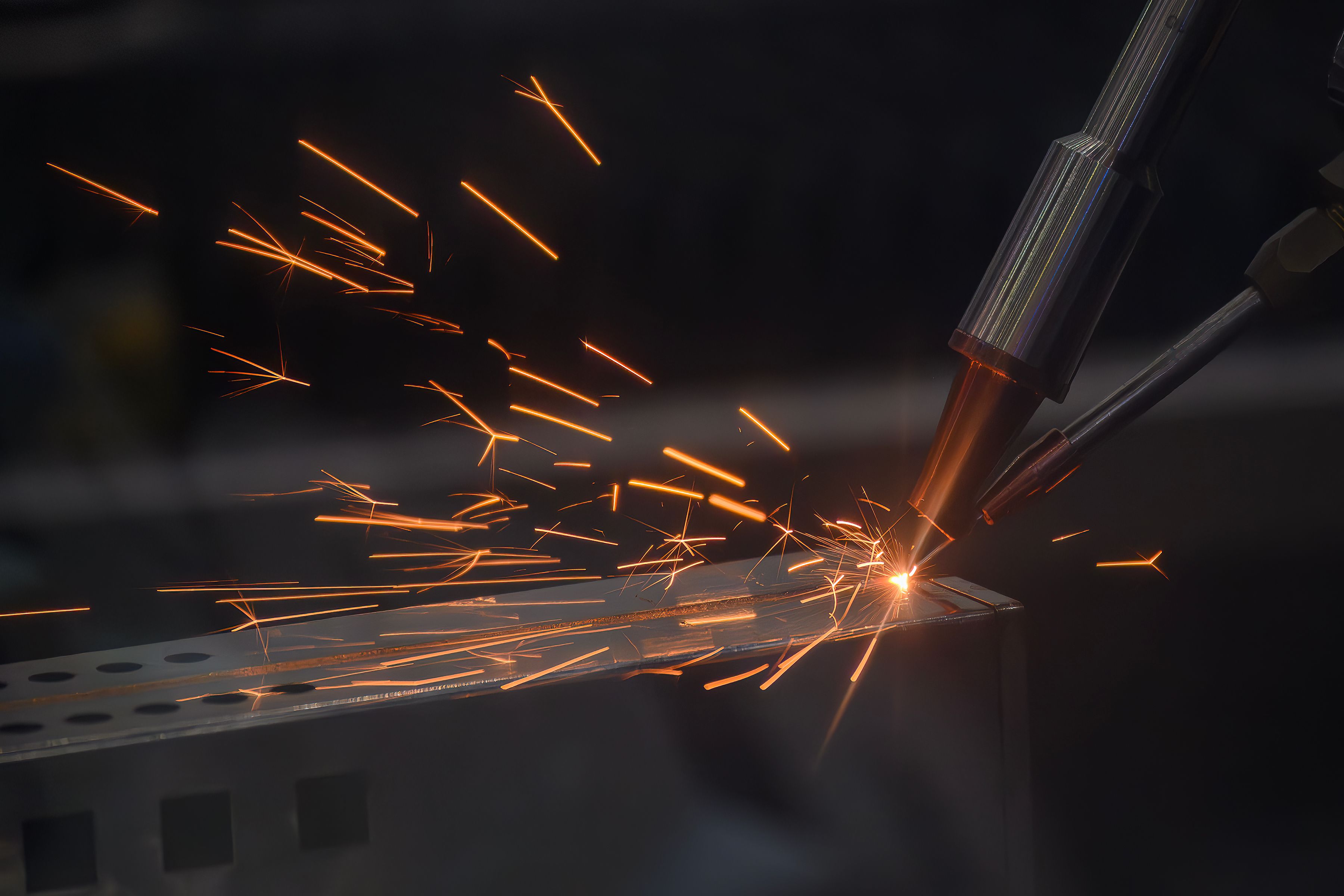

One of Lincoln Electric's most notable innovations is their development of advanced arc welding technologies. These systems have dramatically improved the speed, precision, and safety of welding processes. The introduction of inverter technology, for instance, has been a game-changer, offering greater control and energy efficiency compared to traditional transformers.

Moreover, the company's investment in digital solutions has resulted in the creation of sophisticated welding software. These programs allow for real-time monitoring and diagnostics, enabling welders to achieve optimal results with minimal effort. This integration of digital tools underscores Lincoln Electric's commitment to enhancing user experience and productivity.

Automation and Robotics

In response to the growing demand for automation, Lincoln Electric has expanded its portfolio to include robotic welding systems. These systems provide unparalleled accuracy and consistency, making them ideal for high-volume production environments. By incorporating robotics, companies can achieve faster turnaround times while maintaining superior quality standards.

The use of robotic systems also addresses labor shortages and reduces the risk of workplace injuries, as machines can perform repetitive tasks that would otherwise be physically taxing for human workers. This focus on automation aligns with Lincoln Electric's goal of creating safer and more efficient workspaces.

Commitment to Sustainability

In recent years, Lincoln Electric has placed a significant emphasis on sustainability. The company is dedicated to reducing its environmental footprint by developing eco-friendly products and processes. Their welding consumables are designed to minimize waste and emissions, contributing to a cleaner and greener environment.

Additionally, Lincoln Electric's energy-efficient solutions help businesses decrease their carbon footprint while lowering operational costs. By prioritizing sustainability, the company not only supports global environmental goals but also provides customers with sustainable options that align with modern ecological standards.

Education and Training Initiatives

Recognizing the importance of skill development, Lincoln Electric invests heavily in education and training programs. Their Welding Technology & Training Center offers comprehensive courses for welders of all levels, ensuring that professionals are equipped with the latest techniques and knowledge.

The company's commitment to education extends beyond traditional training methods. They have embraced virtual and augmented reality technologies to provide immersive learning experiences. These innovative approaches allow trainees to practice in simulated environments, enhancing their skills without the risks associated with real-world scenarios.

Future Prospects

As industries continue to evolve, Lincoln Electric remains poised to lead the charge in welding technology innovation. Their ongoing research and development efforts promise exciting advancements that will further transform the field. By staying ahead of trends and anticipating market needs, Lincoln Electric ensures its leadership position well into the future.

Their unwavering commitment to quality, innovation, and sustainability makes Lincoln Electric not just a company but a true pioneer in welding technology. As they continue to push boundaries, they inspire confidence in businesses seeking to elevate their capabilities through state-of-the-art welding solutions.