Essential Applications of Magnet Drills in Steel Construction

RR

Overview of Magnet Drills

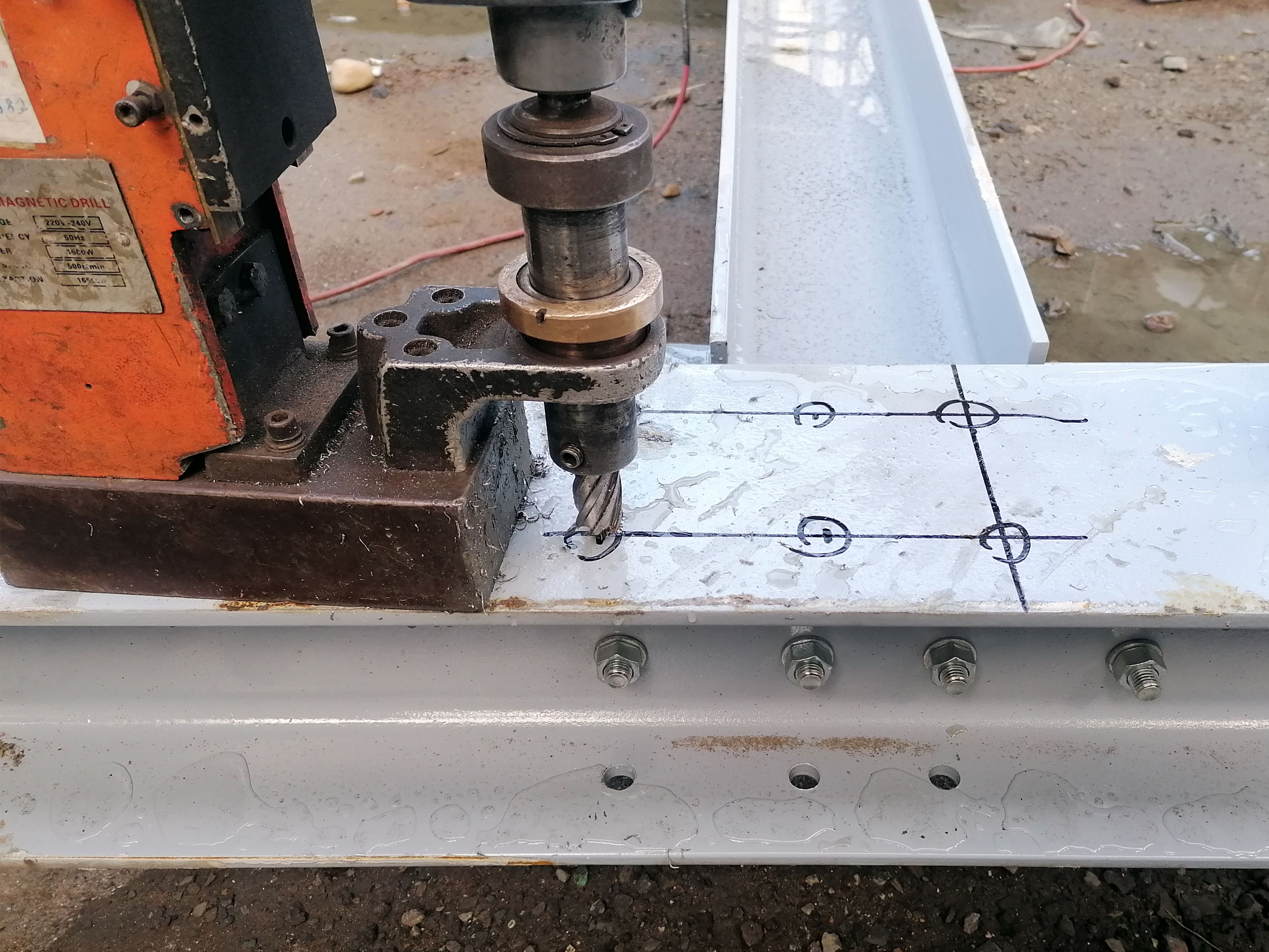

Magnet drills, also known as magnetic drill presses, are a vital tool in the steel construction industry. These portable drilling machines are designed to cut through tough materials like steel with precision and ease. By using an electromagnet to secure the drill to a metal surface, these tools offer stability and accuracy in various applications. Their versatility and efficiency make them indispensable for professionals working on construction sites.

Advantages of Using Magnet Drills

The primary advantage of magnet drills is their ability to deliver precise drilling on vertical and horizontal surfaces. This is particularly beneficial in steel construction, where precision is crucial for structural integrity. Additionally, these drills are compact and portable, allowing workers to easily transport them across job sites and perform drilling tasks in tight or elevated spaces.

Another key benefit is their speed and efficiency. Magnet drills can quickly bore holes into steel, saving significant time compared to traditional methods. They also reduce fatigue for operators due to their stability and ease of use. This increased efficiency translates to cost savings on labor and materials, making them a cost-effective solution for construction projects.

Common Applications in Steel Construction

Magnet drills find applications in various stages of steel construction. Some of the most common uses include:

- Structural Fabrication: Creating precise holes for bolts and fasteners in steel beams and columns.

- Assembly of Steel Framework: Ensuring accurate alignment and fitting of steel components during assembly.

- Installation of Large Structures: Facilitating the installation of bridges, towers, and other large constructions by providing secure drilling on-site.

Safety and Efficiency Considerations

When using magnet drills, safety is paramount. Operators should ensure the drill's magnetic base is securely attached to a clean surface to prevent accidents. Additionally, wearing appropriate personal protective equipment (PPE), such as gloves and goggles, is essential to safeguard against metal shavings and debris.

To maximize efficiency, regular maintenance of the drill is crucial. This includes checking the integrity of the magnetic base, ensuring all components are in good working condition, and replacing worn-out parts promptly. Proper maintenance not only extends the life of the tools but also enhances their performance.

Choosing the Right Magnet Drill

Selecting the appropriate magnet drill for your project requires consideration of several factors. Key aspects include the size and type of materials you'll be working with, as well as the specific tasks you need to perform. It's important to choose a drill with adequate power and capacity to handle the demands of your job site.

Additionally, look for features like variable speed control, adjustable bases, and coolant systems that can enhance functionality and ease of use. By selecting the right tool tailored to your needs, you can ensure optimal performance and results in your construction projects.

Conclusion

Incorporating magnet drills into steel construction projects can significantly improve efficiency, precision, and safety. Their ability to perform accurate drilling on tough materials makes them an essential tool for any professional in the industry. By understanding their applications and maintaining them well, construction teams can leverage these powerful tools to achieve successful project outcomes.