Choosing the Right Magnet Drill: A Guide for North Rhine-Westphalia

RR

Understanding the Basics of Magnet Drills

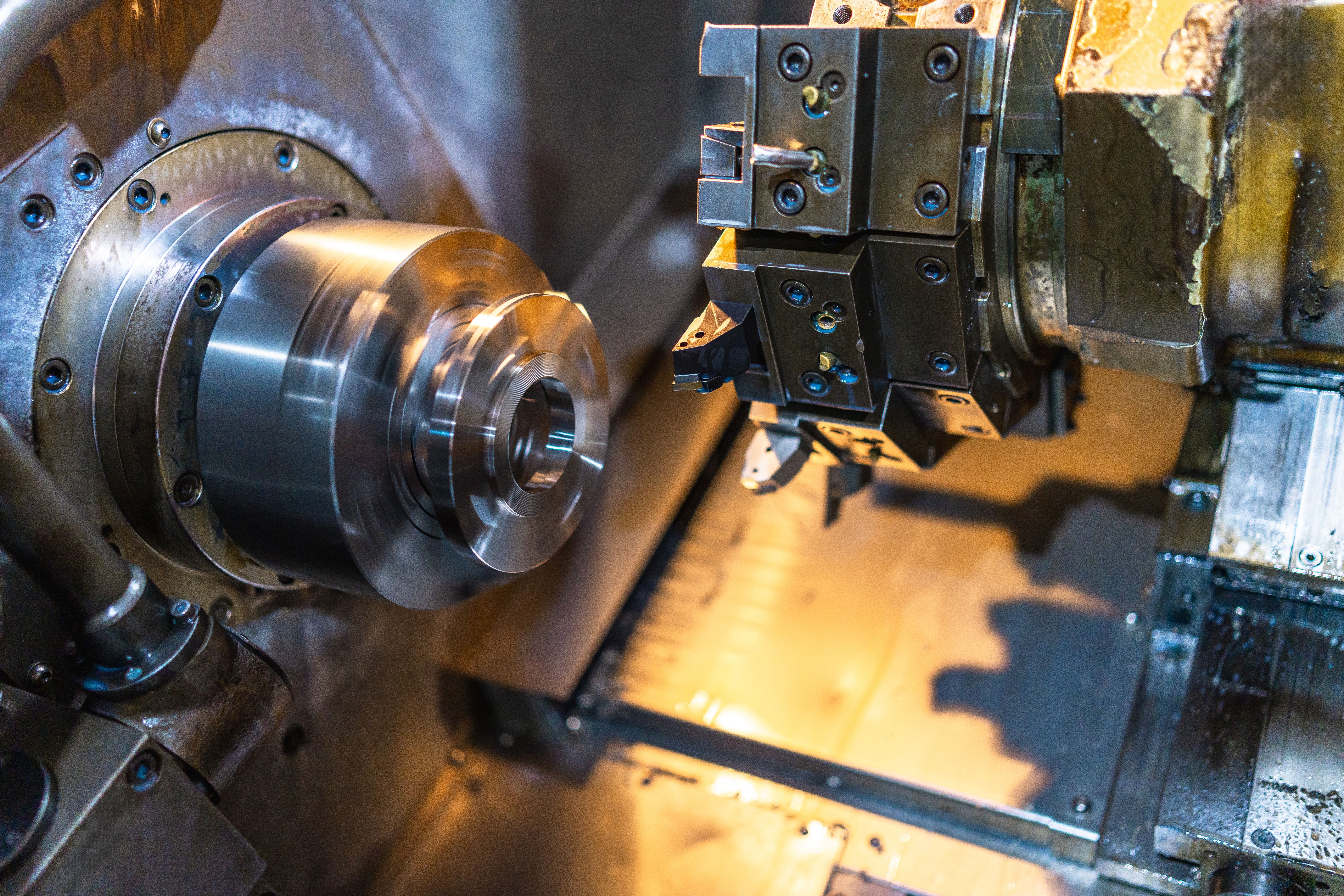

Magnet drills, also known as mag drills, are a powerful tool used extensively in construction and metalworking. They are designed to cut through metal surfaces with precision, thanks to their magnetic base, which securely attaches the drill to steel surfaces. In North Rhine-Westphalia, industries rely on these drills for various applications, making it essential to choose the right one for your needs.

When selecting a magnet drill, it's crucial to understand the different types available. The two primary categories are corded and cordless magnet drills. Corded drills offer continuous power, while cordless versions provide flexibility and portability. Your choice will depend on the specific requirements of your project.

Key Features to Consider

There are several key features to consider when purchasing a magnet drill. First, assess the drill's power and speed. A powerful motor can make drilling more efficient, especially when working with thicker materials. Look for models that offer variable speed settings to accommodate different tasks.

Another vital feature is the weight and size of the drill. For projects that require frequent movement or overhead work, a lightweight and compact design will be beneficial. Additionally, ensure that the drill's magnetic base provides a strong hold to prevent any movement during operation. This stability is crucial for ensuring accurate and safe drilling.

Drill Accessories and Attachments

Your magnet drill's versatility can be enhanced by choosing the right accessories and attachments. These include annular cutters, twist drill bits, and countersinks. Annular cutters are ideal for creating larger holes with precision, while twist drill bits are suitable for smaller tasks.

Consider investing in accessories that are compatible with your specific make and model of magnet drill. This compatibility ensures optimal performance and longevity of both the drill and its attachments. Additionally, some models come with quick-change systems that allow for easy switching between different tools, saving time during projects.

Safety Considerations

Safety should always be a priority when operating a magnet drill. Ensure that you are familiar with the manufacturer's safety instructions before use. Wearing appropriate personal protective equipment (PPE), such as gloves and safety glasses, is essential to minimize the risk of injury.

It's also important to regularly inspect the drill for any signs of wear or damage. Regular maintenance will not only extend the life of your tool but also ensure it operates safely. Always disconnect the power source before performing any maintenance or accessory changes.

Choosing the Right Supplier

When purchasing a magnet drill in North Rhine-Westphalia, choosing a reputable supplier is crucial. Look for suppliers who offer a warranty and reliable customer support. This support can be invaluable if you encounter any issues or need advice on selecting the right product.

Additionally, consider suppliers who can provide after-sales services such as repairs and spare parts. This level of service can significantly enhance your purchase experience and ensure that your magnet drill remains in excellent working condition for years to come.