Choosing the Right Hole Cutter for Your Magnet Drill: Expert Tips from Cologne

RR

Understanding the Importance of Choosing the Right Hole Cutter

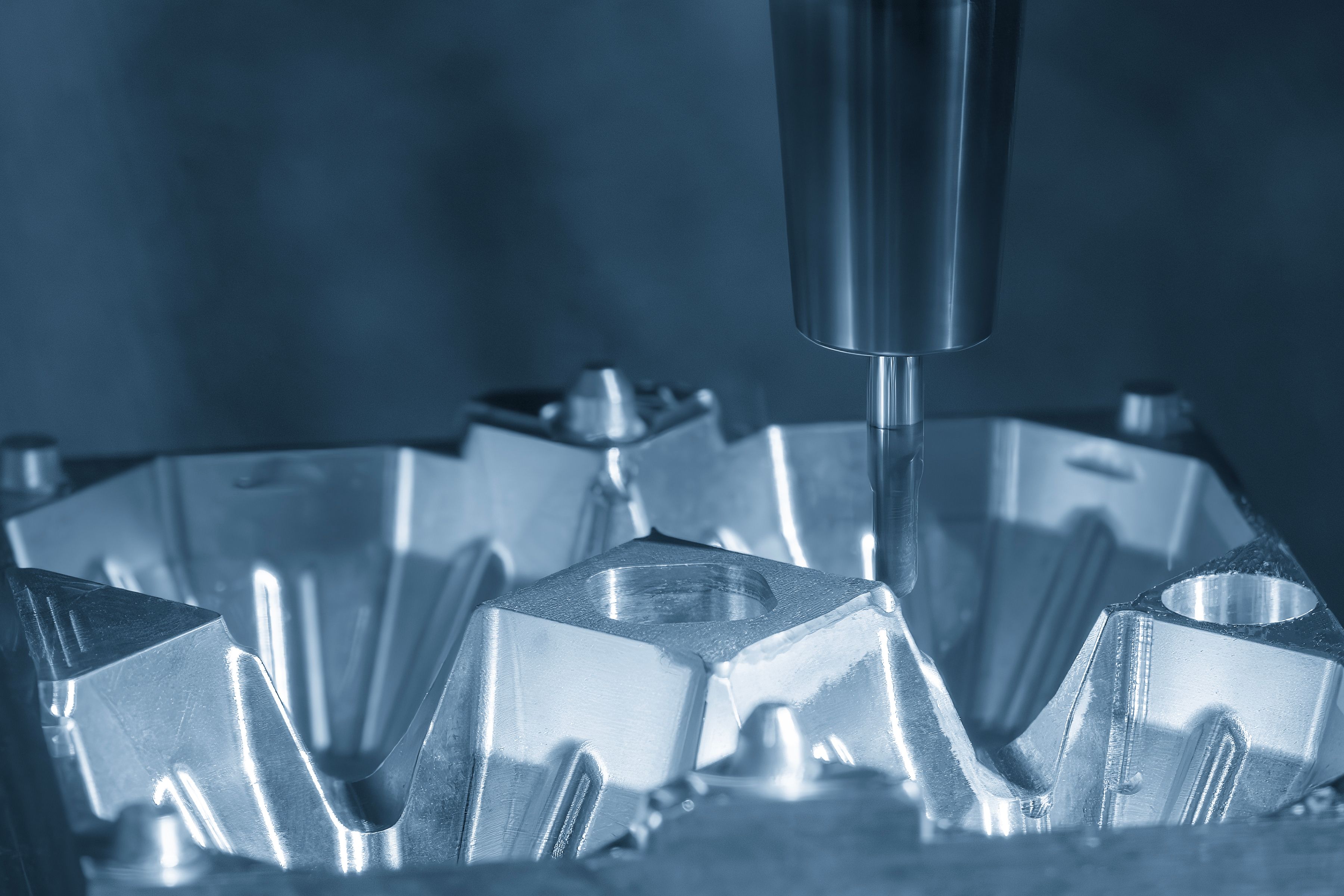

When it comes to using a magnet drill, selecting the right hole cutter is crucial for achieving optimal results. Whether you're a professional or an avid DIY enthusiast, understanding the different types of hole cutters and their specific applications can significantly impact the quality and efficiency of your work. In this guide, we will explore expert tips from Cologne on how to choose the right hole cutter for your magnet drill.

Using the appropriate hole cutter not only ensures precision but also extends the lifespan of your tools. A well-chosen cutter reduces the risk of material damage and enhances the overall performance of your drill. Let's dive into the key factors you should consider when selecting a hole cutter.

Types of Hole Cutters

Annular Cutters

Annular cutters are among the most popular choices for magnet drills due to their efficiency in cutting through metal. These cutters are designed to remove only the outer edge of a hole, leaving a solid core behind. This results in faster cutting speeds and less material waste compared to traditional twist drills.

Available in various sizes and materials, annular cutters are ideal for applications requiring clean and precise holes. When selecting an annular cutter, consider factors such as the material hardness and thickness you will be working with.

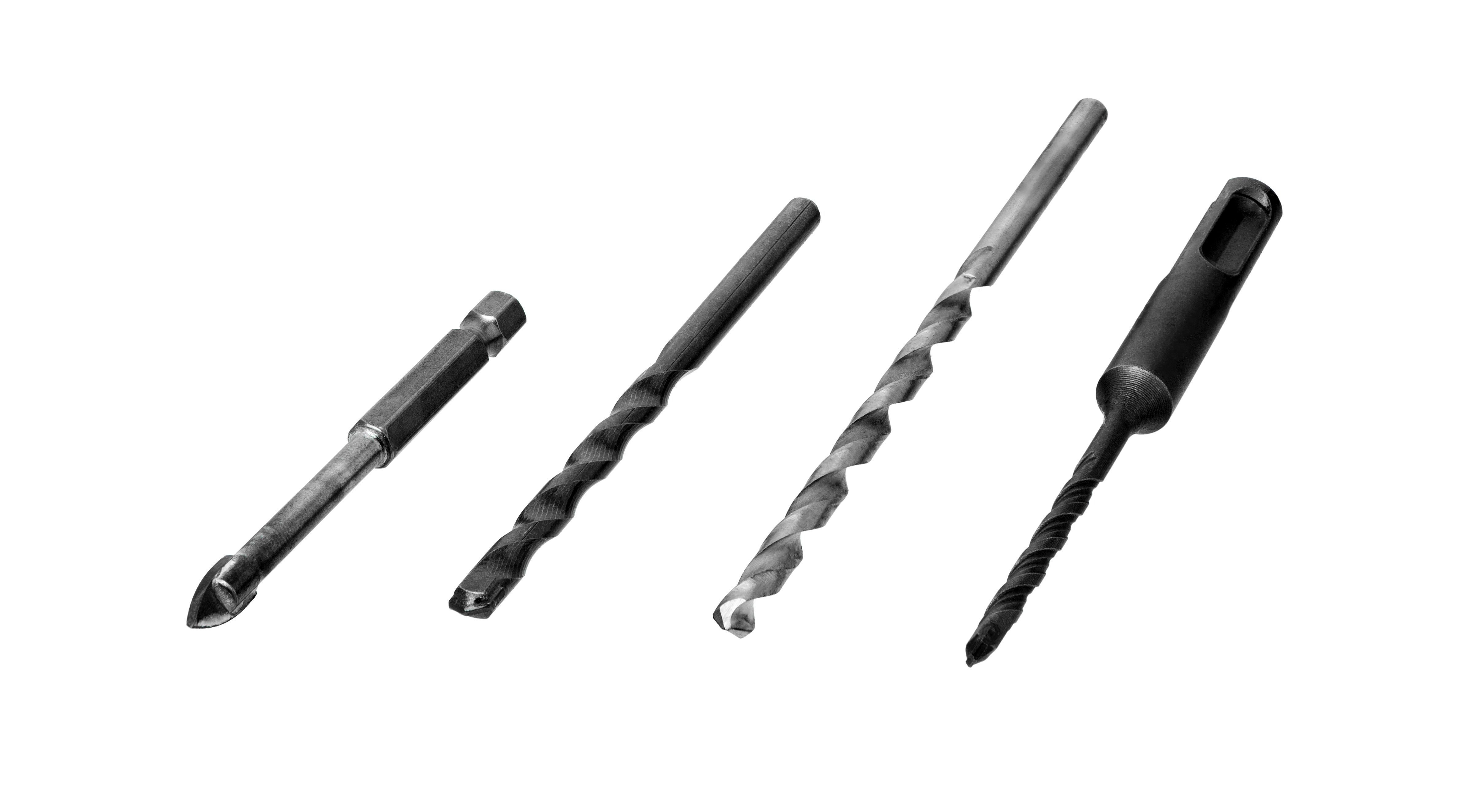

Twist Drills

Twist drills are versatile and suitable for a variety of materials, including wood, plastic, and metal. However, they may not be as efficient as annular cutters when it comes to drilling larger holes in metal. If your project involves multiple materials, having a set of high-quality twist drills on hand can be beneficial.

Factors to Consider When Choosing a Hole Cutter

Material Compatibility

The first step in choosing the right hole cutter is determining the type of material you will be working with. Different cutters are designed to handle specific materials, such as steel, aluminum, or wood. Make sure your cutter is compatible with the material in order to prevent damage and ensure smooth operation.

Size and Depth of Cut

The size of the hole you need to cut is another critical factor. Hole cutters come in various diameters and lengths, so it's essential to select one that matches your project requirements. Additionally, consider the depth of the cut; longer cutters are needed for deeper holes.

Maintaining Your Hole Cutters for Longevity

Proper maintenance is key to extending the life of your hole cutters. Regularly inspect your cutters for signs of wear and tear, such as dull edges or chipped teeth. Sharpening or replacing worn cutters can prevent damage to both your material and your magnet drill.

Additionally, always use cutting fluid when drilling metal to reduce friction and heat buildup. This not only prolongs the life of your cutter but also ensures cleaner cuts.

Expert Tips from Cologne

Professionals from Cologne recommend investing in high-quality hole cutters from reputable brands known for their durability and precision. While these may come with a higher upfront cost, they often prove to be more economical in the long run due to their extended lifespan and superior performance.

Lastly, don't hesitate to consult with experts or manufacturers if you're unsure about which hole cutter to choose. Their insights can help you make an informed decision tailored to your specific needs.