Choosing the Right Annular Cutter for Steel Structures

RR

Understanding Annular Cutters

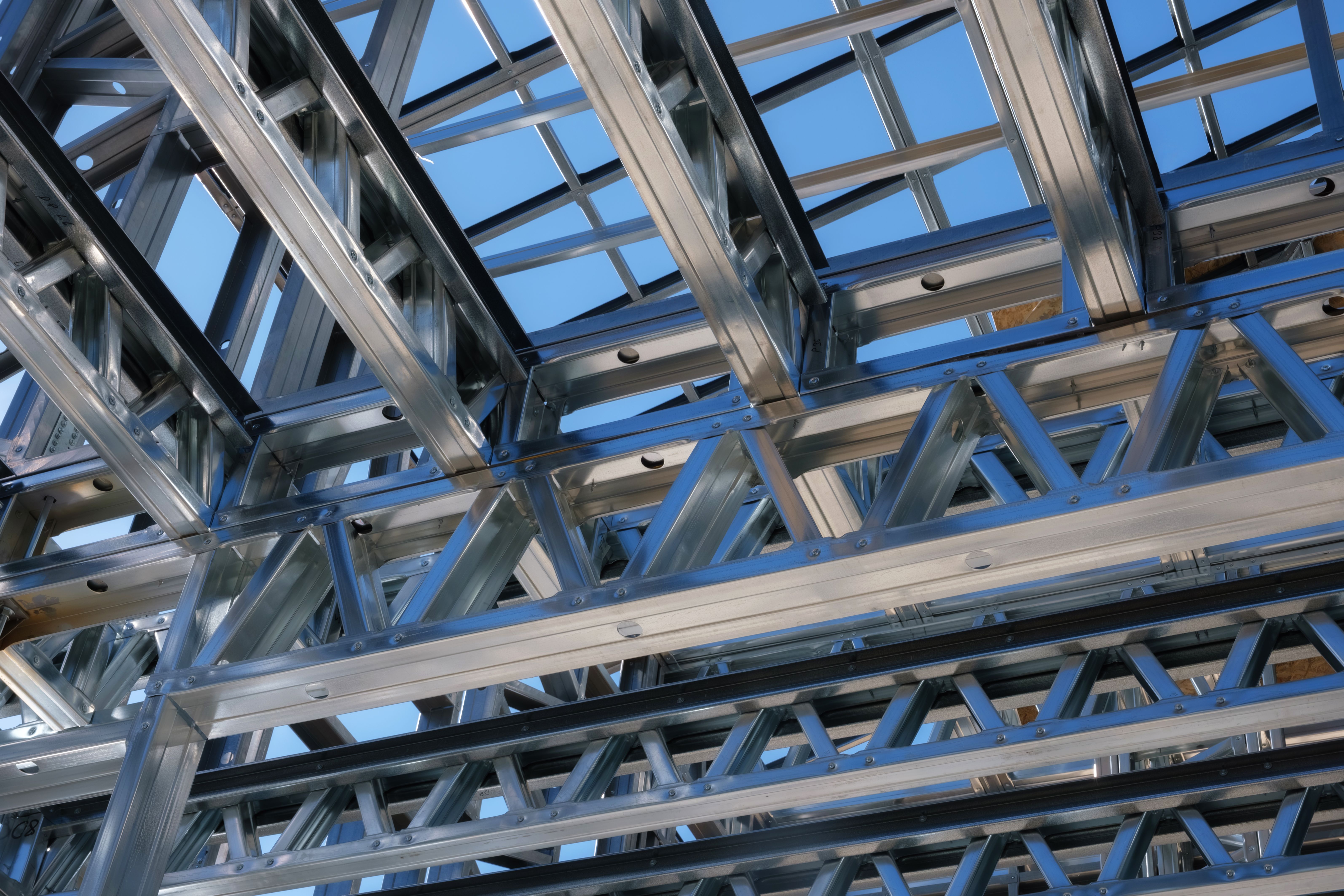

In the world of metalworking, annular cutters are indispensable tools, especially when working with steel structures. They are designed to create precise, clean holes without the pilot hole that traditional twist drills require. Understanding the features and capabilities of annular cutters can significantly impact the efficiency and quality of your work.

Annular cutters, often referred to as core drills or hole cutters, are tubular-shaped drilling tools that cut only the periphery of a hole, leaving a solid slug at the center. This design reduces the amount of material removed, making the process faster and requiring less force. The choice of an annular cutter can influence your project's success, so it's crucial to select the right one based on your specific needs.

Material Considerations

The material of the annular cutter is a primary factor to consider. Most are made from high-speed steel (HSS) or carbide. HSS cutters are suitable for general-purpose applications and offer a good balance between cost and performance. They are ideal for softer materials but can wear out faster when used on hard metals. On the other hand, carbide-tipped cutters are more expensive but offer superior durability and performance, especially for cutting through hard steel.

When working with steel structures, opting for carbide-tipped annular cutters can be beneficial due to their longer lifespan and ability to maintain sharpness even after repeated use. This choice can lead to significant cost savings in the long run by reducing the frequency of tool replacement.

Diameter and Depth of Cut

The diameter and depth of cut are critical parameters when selecting an annular cutter. The diameter should match the size of the hole you need, while the depth must be sufficient to penetrate through the material being cut. Annular cutters are available in a wide range of diameters, typically from 12mm to over 100mm, and varying depths.

If your project involves drilling through thick steel beams or plates, ensure that you choose a cutter with an adequate depth. It is also advisable to consider cutters with a longer depth than immediately necessary to accommodate future projects that may require deeper cuts.

Shank Types and Compatibility

The shank of an annular cutter is another important feature to consider. It determines compatibility with your magnetic drill or other drilling equipment. Common shank types include weldon shanks and universal shanks. Weldon shanks, with their two flat sides, are widely used due to their secure fit and stability during drilling.

Before purchasing an annular cutter, check the specifications of your drill to ensure compatibility. Using a cutter with an incompatible shank can lead to inefficient drilling and potential damage to both the cutter and the equipment.

Cutter Coatings and Lubrication

Cutter coatings can enhance performance by reducing friction and increasing heat resistance. Some common coatings include titanium nitride (TiN) and titanium aluminum nitride (TiAlN). These coatings can extend the life of your cutter by allowing for faster speeds and less wear.

Additionally, proper lubrication is essential when using annular cutters on steel structures. Lubricants reduce heat buildup and wear on the cutter, improving both speed and lifespan. Always use the recommended lubricant type for your specific cutter material.

Conclusion

Choosing the right annular cutter for steel structures involves considering several factors such as material, diameter, depth, shank type, coatings, and lubrication practices. By paying attention to these details, you can ensure efficient drilling operations and extend the life of your tools. Investing in high-quality annular cutters tailored to your specific needs will ultimately lead to better performance and cost savings on your projects.