Choosing the Right Annular Cutter for Steel Structures: Expert Tips

RR

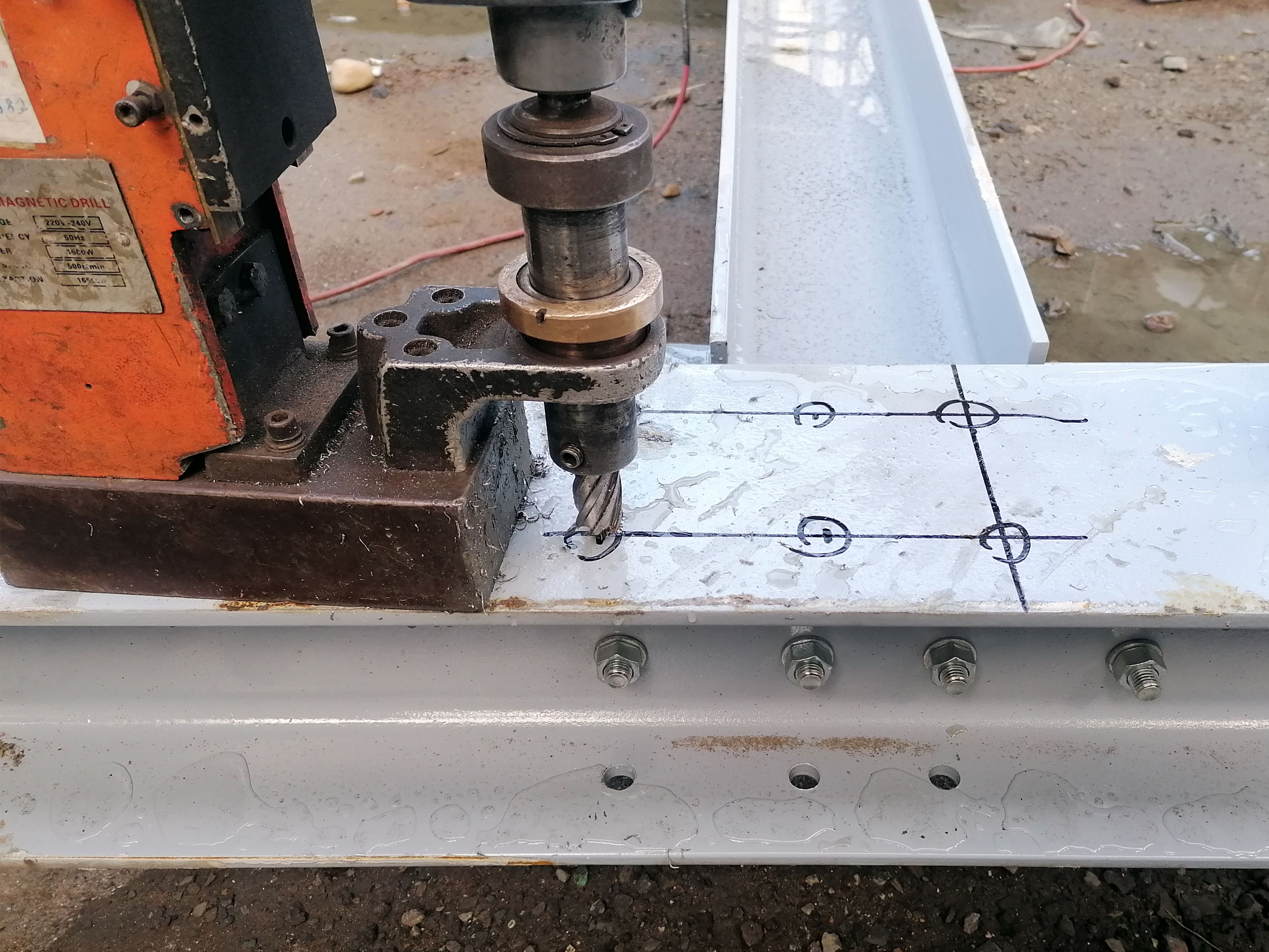

When it comes to constructing steel structures, the choice of tools can significantly affect both the efficiency and quality of your work. One crucial tool in this realm is the annular cutter. Selecting the right annular cutter for steel structures is essential for achieving precise and clean cuts. In this guide, we'll explore expert tips to help you make an informed decision.

Understanding Annular Cutters

Annular cutters are specialized drill bits designed to remove only the material at the perimeter of a hole, thus being more efficient than traditional drill bits. They are particularly useful in creating large diameter holes in steel structures with minimal effort. Understanding their design and usage will help you appreciate why they are preferred for heavy-duty applications.

Material of the Annular Cutter

One of the most critical factors in choosing an annular cutter is the material from which it is made. High-speed steel (HSS) and carbide-tipped cutters are popular choices. HSS cutters are known for their durability and cost-effectiveness, making them ideal for general applications. On the other hand, carbide-tipped cutters offer superior cutting speed and longevity, especially suited for tough materials.

Size and Depth Considerations

The size of the hole you need to cut will determine the diameter of the annular cutter. It's crucial to select a cutter that matches your specifications precisely to avoid any unnecessary adjustments or errors. Additionally, consider the depth of the cut. Annular cutters come in various lengths, so ensure you choose one that accommodates the thickness of the steel you're working with.

Types of Annular Cutters

There are several types of annular cutters, each designed for specific applications. Standard annular cutters are suitable for most steel structures, while specialized types like long-series cutters and pilot pin-equipped cutters offer added benefits for particular tasks. Understanding these differences will help you select the right tool for your project.

Compatibility with Drilling Machines

Before purchasing an annular cutter, ensure compatibility with your drilling machine. Most cutters are designed to fit standard magnetic drill presses, but it's essential to verify that your equipment supports the cutter's shank size and type. This compatibility will ensure smooth operation and prevent any damage to your tools or machine.

Maintenance and Care

Proper maintenance and care of your annular cutters can significantly extend their lifespan. Regular cleaning to remove debris and applying cutting oil during use can prevent wear and tear. Additionally, storing them properly when not in use will ensure they remain sharp and ready for your next project.

Conclusion

Choosing the right annular cutter for steel structures involves considering several factors, including material, size, type, and compatibility with your equipment. By following these expert tips, you can enhance your drilling efficiency and achieve precise results. Investing in a quality annular cutter not only improves your work outcome but also ensures safety and durability in your construction projects.