Choosing the Right Annular Cutter for Steel Structures: A Guide for Builders

RR

When it comes to constructing steel structures, precision and efficiency are paramount. One essential tool that plays a critical role in achieving these goals is the annular cutter. However, with a variety of options available on the market, choosing the right annular cutter for your specific needs can be a daunting task. This guide aims to help builders make informed decisions when selecting annular cutters for their projects.

Understanding Annular Cutters

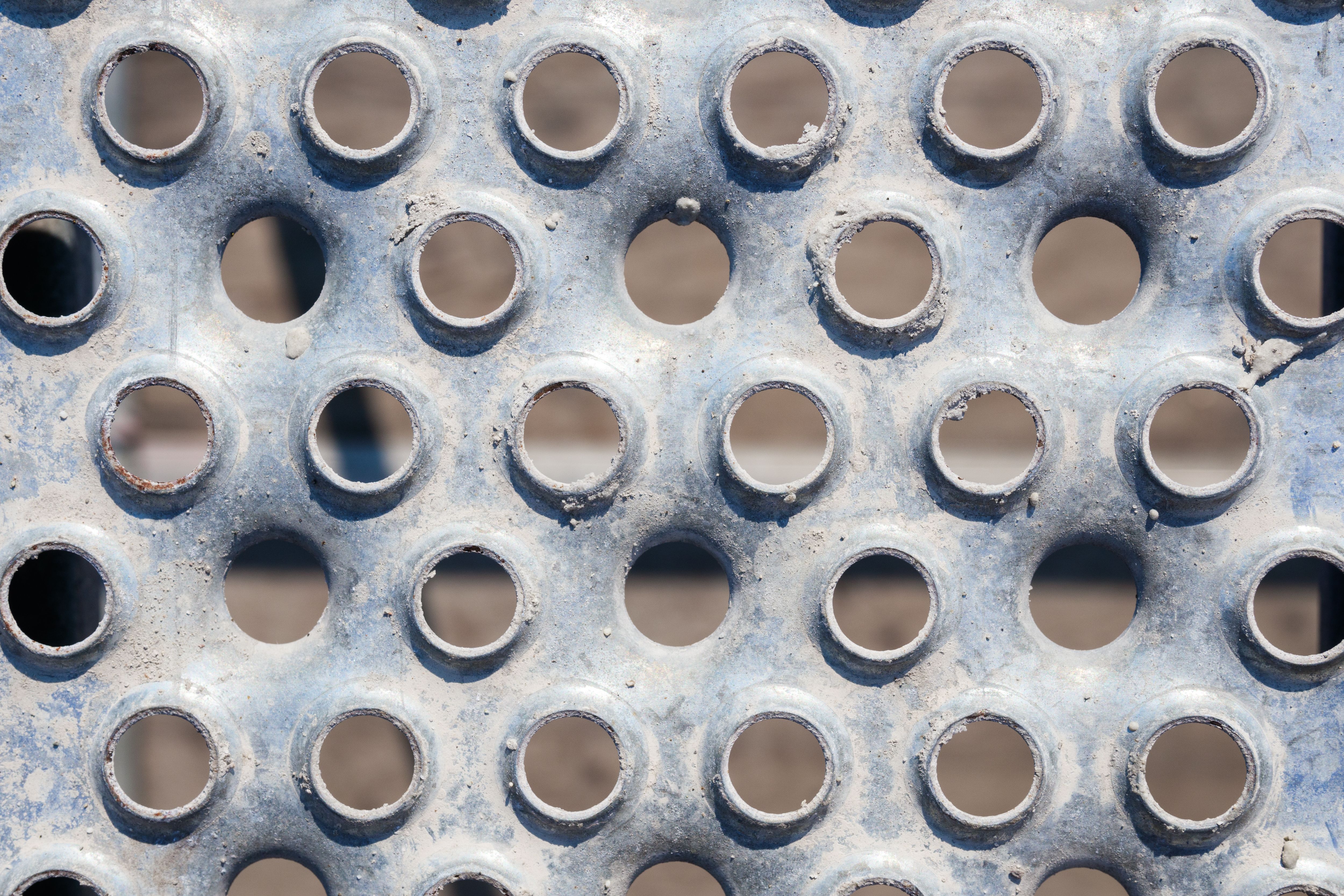

Annular cutters are specialized tools used for drilling precise holes in metal structures. Unlike traditional twist drills, annular cutters cut only the perimeter of the hole, leaving a solid slug at the center. This design allows for faster drilling with less effort and produces cleaner, more accurate holes. Builders must understand the basic functionality of annular cutters to select the most suitable one for their tasks.

Material Considerations

The material of the annular cutter is a crucial factor to consider. High-speed steel (HSS) and carbide-tipped cutters are common choices. HSS cutters are cost-effective and suitable for general-purpose drilling in softer metals, while carbide-tipped cutters are more durable and capable of cutting through tougher materials like stainless steel. Builders should assess the materials they will be working with to determine the appropriate cutter material.

Another aspect to consider is the coating of the annular cutter. Coatings such as titanium nitride (TiN) or cobalt can enhance the performance and longevity of the cutter by reducing friction and wear. Builders working on extensive projects may find these coatings beneficial for maintaining efficiency over time.

Size and Depth of Cut

The size of the annular cutter, including its diameter and depth of cut, is another critical factor. Builders should ensure that the cutter's diameter matches the required hole size for their project. It's also essential to consider the depth to which the cutter can drill. Annular cutters come in various lengths, so selecting one that meets your project's specifications is vital for achieving desired results.

Compatibility with Drilling Machines

Annular cutters must be compatible with the drilling machines used on site. Most annular cutters have a standard shank size, but it's important to verify that it matches your drill's arbor size. Additionally, some cutters may require specific adapters or accessories to fit properly. Ensuring compatibility will prevent unnecessary downtime and ensure smooth operation during construction projects.

Moreover, consider whether you'll need a pilot pin with your annular cutter. Pilot pins assist in aligning the cutter and starting the hole accurately, especially useful when drilling through thicker materials. This small addition can significantly impact precision and ease of use.

Choosing Trusted Brands

When investing in annular cutters, opting for reputable brands known for quality and reliability can make a difference in your building projects. Trusted manufacturers often provide better customer support, detailed specifications, and consistent product performance. Researching reviews and seeking recommendations from industry peers can help identify reliable brands.

Maintenance and Care

Proper maintenance is essential to prolonging the life of your annular cutters. Regularly inspect them for signs of wear or damage, such as dull edges or chipped teeth. Keeping them clean and lubricated can also enhance their performance and lifespan. Investing time into maintaining your tools can result in better project outcomes and cost savings in the long run.

In conclusion, selecting the right annular cutter involves considering several factors, including material compatibility, size, machine compatibility, brand reputation, and maintenance practices. By evaluating these elements thoughtfully, builders can choose annular cutters that enhance efficiency, precision, and overall project success.