Choosing the Best Magnet Drill for Precision Drilling

RR

Understanding Magnet Drills

Magnet drills, also known as magnetic drill presses, are essential tools for precision drilling in metalworking and construction. These portable tools use a powerful magnet to adhere to metal surfaces, providing stability and accuracy during the drilling process. Whether you're a professional or a DIY enthusiast, selecting the right magnet drill can greatly influence the quality of your work.

Choosing the best magnet drill involves understanding its components and how they contribute to its performance. Key features include the motor power, drill size, and magnet strength. Consider these aspects carefully to ensure you select a tool that meets your specific drilling needs.

Key Features to Consider

Motor Power

The motor power of a magnet drill determines its ability to handle different materials and thicknesses. Typically, magnet drills come with motors ranging from 5 to 15 amps. For heavy-duty tasks, a higher amperage motor is recommended as it provides greater torque and efficiency.

Drill Size and Capacity

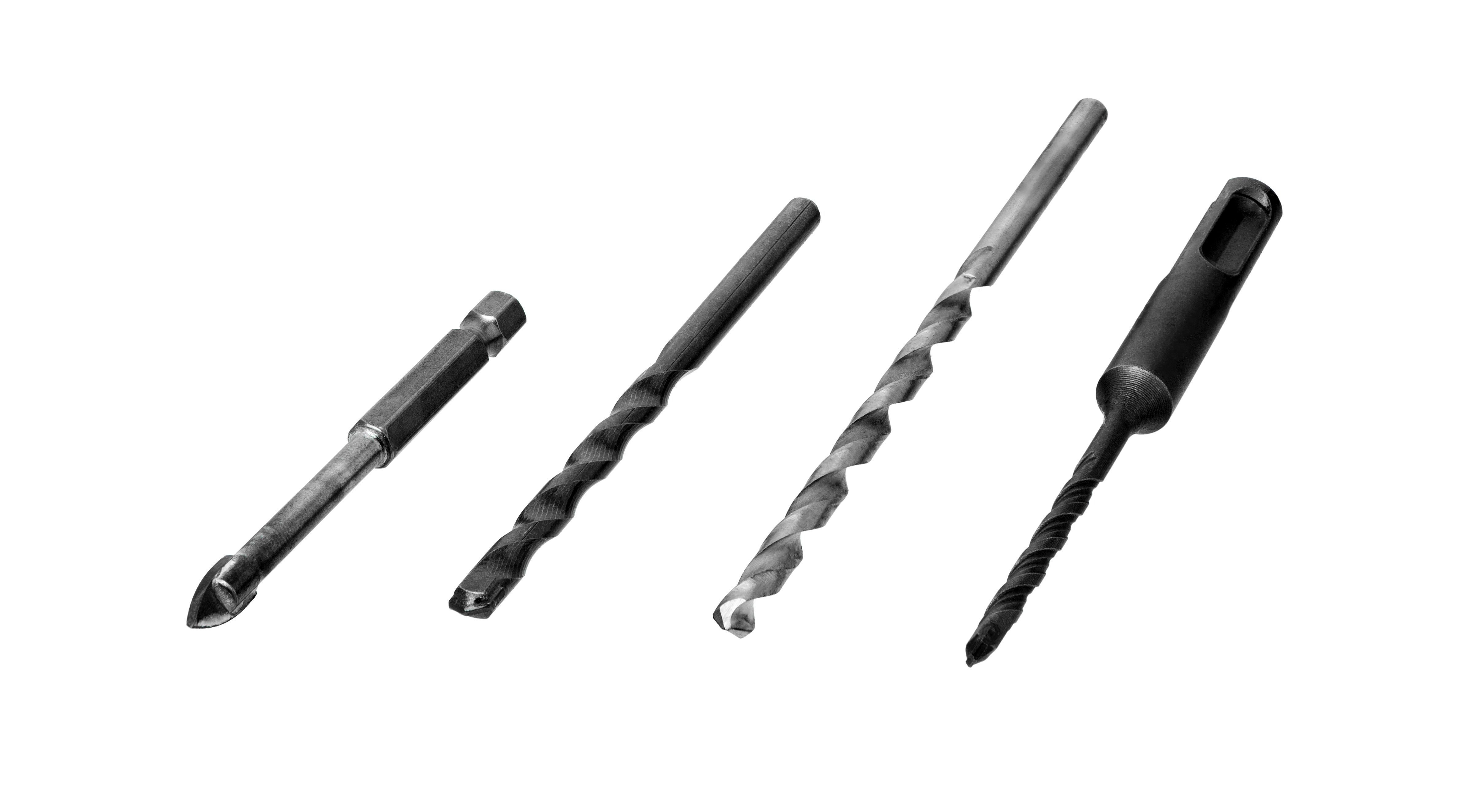

The size and capacity of the drill bit you plan to use are crucial factors. Standard magnet drills can accommodate bits that range in size from ½ inch to 2 inches in diameter. Ensure that the drill you choose can handle the bit size required for your projects. Additionally, consider the depth of cut the drill can achieve, as this will affect its versatility.

Magnet Strength

The strength of the magnet is vital for maintaining stability while drilling. A strong magnetic adhesion ensures that the drill does not slip or move during operation, leading to precise and accurate cuts. Look for drills with magnets that provide a holding force suitable for the thickness and type of material you are working with.

Additional Considerations

Speed Settings

Variable speed settings allow for greater control over the drilling process. Some magnet drills offer multiple speed options, enabling users to adjust the speed based on the material and bit size. This feature is particularly useful when working with different metals or when precision is paramount.

Portability and Weight

If your projects require mobility, consider the weight and portability of the magnet drill. Lighter models are easier to transport and handle, especially in tight or elevated spaces. However, ensure that the reduction in weight does not compromise the tool's power and performance.

Safety Features

Safety should always be a priority. Look for drills with built-in safety features such as overload protection, automatic shut-off, and secure locking mechanisms. These features help prevent accidents and extend the life of your tool.

Conclusion

In conclusion, choosing the best magnet drill involves evaluating several factors including motor power, drill size, magnet strength, speed settings, portability, and safety features. By carefully considering these aspects, you can select a magnet drill that meets your specific needs and enhances the quality of your drilling projects. Investing time in research will pay off in precision and efficiency on every job.